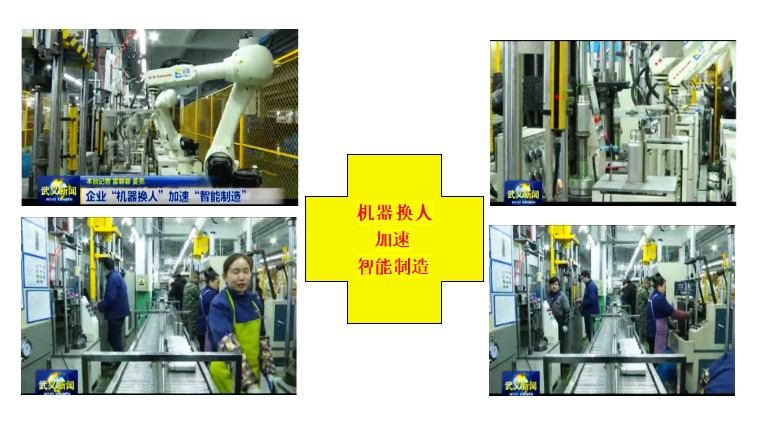

In recent years, with the increasing employment, "machine replacement" has become the current trend and trend. Follow the trend, implement machine replacement, accelerate intelligent manufacturing. Tetra Automation currently serves the following four areas in the robotics industry:

1, heat conduction tube: automatic feeding, loading and unloading robot;

2. Hardware processing: automatic drilling tapping feeding and unloading robot;

3, metal polishing class: polishing robot.

4, insulation cup class: automatic loading and unloading robot;

The following introduces the thermos cup type automatic loading and unloading robot. Recently, in Zhejiang thermos cup newly opened production line, almost see what workers, only a fully automatic assembly line, is conveying their own products, next to the manipulator after the completion of product processing, to the next manipulator. It is understood that the traditional production line needs 11 to 12 people per shift, and can produce about 5,000 to 6,000 sets of cups every day. When the new smart manufacturing line is used, only three people are needed. Machine replacement labor cost is greatly reduced, product quality is improved, safety accidents are also reduced. As a result, more and more enterprises are using robots.

Zhejiang Feijian Group "Lingxian 20" anniversary celebration "Leap 20 years sword tit

2024-08-202021 Shanghai Jinhua Week opens! A total of 16 projects were signed

2021-07-20Industry leaders of Cup Industry Association visited the customer site

2021-05-31Enterprise "machine replacement" accelerate "intelligent manufacturing"

2021-03-03Company building activities

2020-07-28Kawasaki robot and Dongguan special Union to help the vacuum insulation cup container industry

2019-09-25Kawasaki leaders visit our company to guide our work

2019-06-13Gather strength, forge ahead

2019-06-01Breakthrough Award for new talent

2019-03-19The school and enterprise jointly build intelligent manufacturing class, and set up technical talent

2019-03-06